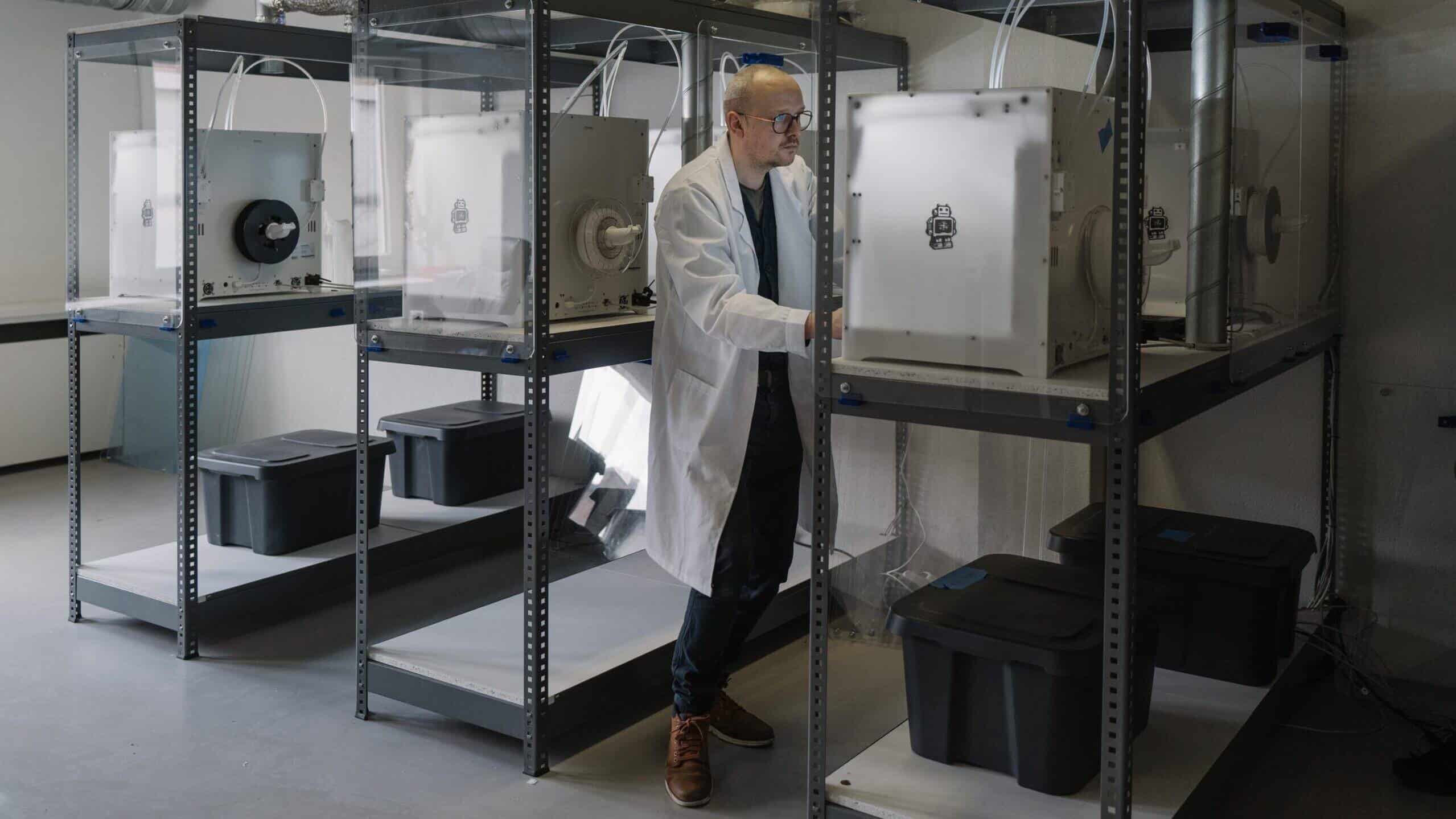

The 3D printers that ETH spin-off 9T Labs sells aren’t just cutting-edge, they also look pretty cool. Who decides how modern machines looks like and what is the reasoning behind it? Industrial Designer Wolfgang Meyer-Hayoz has the answers.

Founder and CEO, Meyer-Hayoz Design Engineering

Wolfgang studied mechanical engineering, visual communication, and industrial design and graduated from the Stuttgart State Academy of Art and design. In 1985, he founded Meyer-Hayoz Design Engineering, a company that advises startups, SMEs and global companies on Design Strategy, Industrial Design, User Interface Design, User experience and Communication Design. The companies employ Industrial Designers in two offices in Switzerland and Germany. Wolfgang was President of the Swiss Design Association and member of various other associations, as well as a juror in international design award, for example in Switzerland, Germany, Singapore and China.

What brought you to study design?

I always had an interest in arts and painting, but my parents told me to study something more solid, so I opted for mechanical engineering. But I realized that this career would not fulfill me. After my studies, I joined the Academy of Art and Design and had the luck to study under Professor Klaus Lehman. His classes were small and allowed interdisciplinary work, so I also attended classes by Prof. Kurt Weidemann, probably the most formative graphic design and typographer of the 20th century in Germany who created works for Deutsche Bahn, Porsche, Zeiss, Daimler and others. I also met Prof. Max Bense, an important semiotician who, before his time in Stuttgart, taught at the legendary college for design in Ulm. For me, studying design was an epiphany. At that time, it was a small world. I remember writing, as a young student, to the famous designer Dieter Rams, head of the design department at Braun, who became famous for his 10 design principles. I wasn’t happy with a detail of a stereo system which I wanted to buy from his company. He even wrote back, explaining that it would be changed in the next production run. I was finally sure I had found my vocation. Today, the dynamic is of course completely different. In China, more than 15 million people are working as designers.

“Design renounces the aesthetic absolutism of art and seeks the aesthetics of use.”

What does an industrial designer do?

The scope of what a designer does has evolved dramatically over time. While aesthetics used to be the focus of broad design work, Otl Aicher was an important pioneer for a different perspective. He explained that design renounces the aesthetic absolutism of art and seeks the aesthetics of use. He is best known for the pictograms that stand for the different sports at the Olympics, which he introduced in 1972 in Munich. Otl also worked for the lighting business Erco, and he challenged the view that a designer should only think about what features a lamp might have. Erco is in the business of light, he said, and design and communication should see light as a source of inspiration that opens new avenues for a family-owned business, and explore the business opportunities that lie in composing and controlling light, too.

In more general terms I’m convinced, industrial designers should ask themselves in what markets a company is active in, what the context is in which the product will be used, how people will interact with it, and consider the feedback the company receives from its customers. The goal of the industrial designer should be to bring a different perspective to a company, one that helps to open up the tunnel vision people working inside the company might have. Only then comes the actual design process with scribbles, concept studies and first CAD models. Talking about these first ideas can set a productive thought process in motion and show how simplifications and savings can be achieved. Only then comes the stage when precise measurements and specifications are defined.

You don’t only work with big multinational companies but also with startups. You and your team designed, for example, the 3D carbon fiber printers from our portfolio company 9T Labs. How did this collaboration start?

It was shortly before Christmas 2019 when we received the first call from them. Their goal was to be able to show the design and a teaser at a trade show in Paris in March 2020. 9T Labs’ team has incredible drive, and their product sounded very intriguing to us. So, we put in a lot of effort while they still continued to develop the product on their side. Finally, the trade show was canceled, but thanks to rendered images we were still able to convey a realistic picture of what 9T Labs’ technologies and competencies are.

“We wanted to communicate the longevity and sophistication these printers stand for.”

9T Labs’ printing and fusion module do look cool and elegant. But honestly, would it make a difference if they were just ugly-looking beige boxes? They are capital goods, after all.

When you talk to Martin, Giovanni, Chester, and the other team members of 9T Labs, you can feel their enthusiasm for the completely new and powerful technology they are developing. Their 3D printing technology enables clients to build functional parts that are highly optimized in terms of strength and weight reduction. This purpose, this DNA of the company needs to be visually represented, because a startup doesn’t have brand recognition yet. We wanted to give these printers an individuality that lets people build a formal relationship with them, and we wanted to communicate the longevity and sophistication they stand for. It is of utmost importance that an industrial product like this shows its durability visually. This is not a consumer good that is outdated next spring, it will last for a decade or two. We used open structures to make the printing process more tangible, and the black color helps to dissipate the heat that is used in the printing modules.

How different is it for you as a designer to work with a startup instead of a traditional firm?

Bigger companies have a lot more predefined boundaries that a designer has to respect and cannot change. Sometimes the dimensions of a new machine or a new device are already set, because the clients who replace an older one want it to fit in the same space, for example. The users also have their habits, and those need to be accounted for as well. In general, a lot depends on the dynamism of a larger company, but the creative and design processes are similar.

And what is the difference between designing an industrial product and, say, a chair?

There are thousands of chairs in the world already, but as a designer, you can start anew, driven only by your own perception, without any specification. Of course, this changes when a contract exists, and new production technologies are required or new materials are experimented with. Personally, 1988, I came across the material carbon through the prototype of the “lightlight” Chair by the well-known designer Alberto Meda, courageous and groundbreaking development by the company Alias / Italy for the living area. Industrial design necessarily involves a lot of interaction between designers and engineers. In 9T Labs’ case, we needed to work with a specific size of the printer chamber for technical reasons, for example. Industrial design is driven by technological innovation, and also increasingly by new materials. Therefore, we also work closely with Prof. Sascha Peters material and technological agency in Berlin. We are also active in life sciences and healthcare, a field not many designers are active in. For instance, we also work with the MedTech startup Hemotune, where the focus was on the usability and ergonomics of their blood purification machine. And finally, because I’m on the jury of the Red Dot Design award, I’m constantly exposed to novel concepts, and I think it is highly interesting what is coming from Asia and China in terms of design.

Is there a strong cultural difference in design?

Increasingly less so. At a furniture fair, there might still be an influence of Asian tradition, but in industrial design, the European, more specifically German and Swiss design philosophy is clearly visible even in Asia, because it is perceived as sophisticated. There has been a rich exchange of ideas between Europe and China after Deng Xiaoping’s opening of the market.

What do you tell people who might be convinced that design is useful, but shy away because it sounds expensive?

About 85% of the information we take in comes through our eyes. Design can build the image of a company, its seriousness and reliability. In today’s competitive environment, you need to showcase your technology and show the market your company’s dynamism, it would be foolish not to do that. If you talk about the cost, you also need to think about what bad design and bad usability will cost you. There are studies that show how integrally design-oriented companies perform much better on the stock exchange. Red Dot Advanced Studies and the Design Management Institute in Boston has published a lot about the value of design, and even McKinsey confirmed in an extensive study that design processes can accelerate transformation processes in companies. For me, design means that you’re able to go in the direction you want to go with more reassurance.

Written by

WITH US, YOU CANCO-INVEST IN DEEP TECH STARTUPS

Verve's investor network

With annual investments of EUR 60-70 mio, we belong to the top 10% most active startup investors in Europe. We therefore get you into competitive financing rounds alongside other world-class venture capital funds.

We empower you to build your individual portfolio.

More News

23.09.2021

“When the stars align, you can’t wait”

In this interview, entrepreneur and investor Gaëtan Marti recounts how difficult it can be to find financing for a startup, how he bootstrapped Atracsys and eventually, despite different plans, sold it to a big MedTech company.

08.12.2020

3D printing moves beyond prototyping

The hype about consumer 3D printing that was at its height a few years ago has died down. But recent developments have led to advances in the technology and to its adoption in manufacturing functional parts. Aleksander Ciszek, CEO of 3D printing software startup 3YOURMIND explains the reasons why.

04.11.2019

“Hardware that scales has enormous financial potential”

Martin Eichenhofer, CEO and co-founder of 9T Labs, explains how it all started and why their first customers are happy to work with their first product.

Startups,Innovation andVenture Capital

Sign up to receive our weekly newsletter and learn about investing in technologies that are changing the world.