Developing technology is one thing, finding a market for it is a completely different story. Startup IRUBIS found out by chance that its single-use component is perfectly suited for biotech companies and developed a system tailored for the biopharma industry. In this interview, co-founder Anja Müller explains why.

Co-founder and COO, IRUBIS

Anja Müller co-founded IRUBIS in 2017 together with Alexander Geissler and Lorenz Sykora-Mirle. IRUBIS’ technology allows continuous bioprocess monitoring and glucose control without any contamination risk. IRUBIS’ monitoring device uses spectroscopy, a field that Anja has studied during her master’s studies in Physics at the Technical University of Berlin and at her master thesis at the European Synchrotron Radiation Facility. At that time, she also took part in the Femtec career-building program.

Whereas traditional pharmaceuticals are the result of chemical synthesis, biopharmaceuticals are proteins used as therapeutics that are so complex that they can only be synthesized from living cells. Since the first biopharmaceutical hit the market in 1982, they have become a big business too. The biologics market (a synonym for biopharmaceuticals) was worth USD 300bn in 2020 and is expected to double in size in the next 6 years.

Biologics are a delicate thing to produce. The biotech industry uses bioreactors, essentially high-tech tanks, to culture cells in a controlled environment. These cells might produce antibodies, insulin, or vaccines. To do their job, they need nutrients, for example, glucose (a simple sugar). Today, glucose concentration in most bioreactors is monitored and regulated manually. Lab technicians need to take samples, analyze them and then add glucose, if necessary, every day (and weekends are no exception). This is not only cumbersome and suboptimal but also introduces the risk of contamination. A contaminated bioreactor can mean significant lost profit (hundreds of millions of EUR in the worst case).

The Startup IRUBIS has developed a device for automated monitoring and control of glucose concentration in a bioreactor. It is based on a measuring method called spectroscopy. IRUBIS’ system saves manual effort in the laboratory and ensures that the cells are always optimally supplied. This, in turn, increases the production yield. Currently, the device can measure the two most important parameters, glucose, and lactate (a substance produced by cells as they metabolize glucose). However, IRUBIS is working on being able to measure for example glutamine, glutamate, and ammonium soon but also protein and excipient concentration as well as aggregations.

“At a trade fair, an expert from the biopharma industry asked us why we didn’t try bioprocess monitoring as a use case, and it turned out that this was a genius idea.”

IRUBIS uses spectroscopy to analyze glucose levels in bioreactors. How does that work?

Spectroscopy is an established method to analyze samples and has been around for decades. The method we use is called attenuated total reflectance, ATR, and can analyze samples without further preparation. In easy words, we illuminate the sample with infrared light, which is partially absorbed, and based on what is missing when it comes back, we can establish a chemical fingerprint.

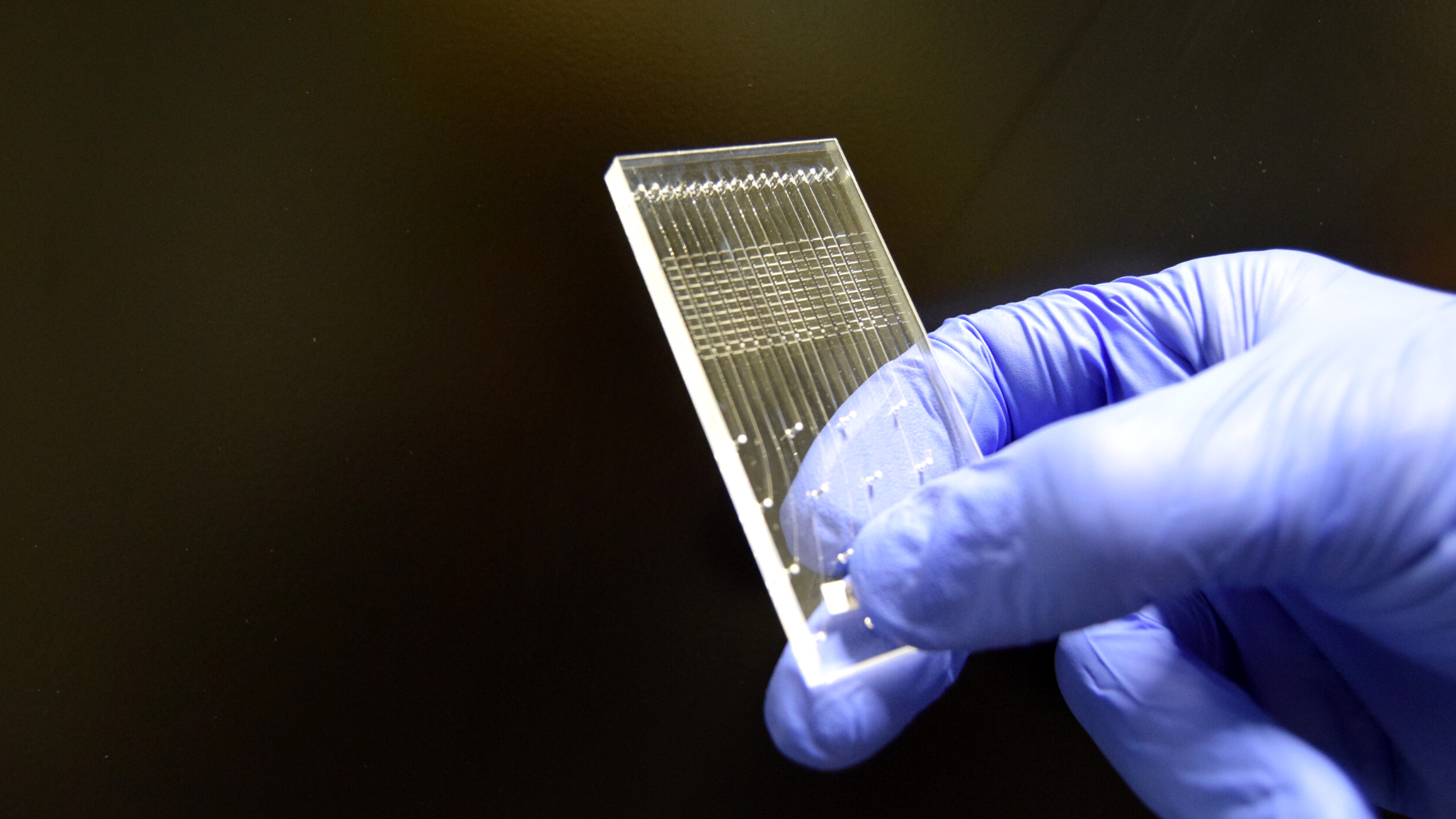

In the past, ATR spectroscopy used mostly diamonds as ATR crystals, which obviously are expensive and have to be reused. We, however, improved the ATR crystal and use silicon crystals that are quite cheap as they can be mass-produced with semiconductor manufacturing processes. When we started, we tried to enter blood analytics with our method, but it became apparent that it wasn’t the optimal use case. At a trade fair, an expert from the biopharma industry asked us why we didn’t try bioprocess monitoring as a use case, and it turned out that this was a genius idea. Our method brings a huge improvement and eliminates the risk of contamination because it is a closed system.

Your current device Monipa measures two parameters, glucose, and lactate. Why just these two?

The advantage of spectroscopy is that we can measure all molecules that vibrate. We initially focused on these two parameters because glucose does not only need to be measured but is also controlled in bioreactors. But we can and will add other parameters. We’re already doing pilots with customers who want to use Monipa in the downstream processes too.

What is the difference between upstream and downstream in bioprocessing?

Upstream is the cultivation of mammalian cells that produce the proteins which will eventually be used as therapeutics. It’s a complex process and you need to control a lot of parameters such as temperature, pH level, and, as explained, glucose concentration. Downstream is the process of taking everything out except the proteins that you want and need to be purified. We did a proof of concept already and showed that we can monitor important downstream parameters such as protein and excipient concentration. [Excipients are substances that aid the production process but do not have any therapeutic use.] The main thing we had to adapt to achieve this is a modification of our analytical software. We’re currently finalizing the prototype and testing it. The good thing is that our next-generation device Monipa 1 can be used for both upstream and downstream applications and is smaller than our current device. It fits in the cabin luggage which comes quite handy when flying to customers to demonstrate it.

Invest in Startups

As one of Europe’s most active venture capital investors, we grant qualified private investors access to top-tier European startups. With investments starting at EUR/CHF 10’000, you can build your own tailored portfolio over time and diversify across stages and sectors.

Who are your clients and why do they buy a Monipa?

Our clients are biotech companies large and small. Their question isn’t if they need it or not. It is a no-brainer. They want to know if it really works as advertised. This is why they want a demo, or pilot project before they buy a device. They like that we use single-use flow cells and that our device is ready after just one initial reference measurement. Other devices need 3-5 months of calibration to work and need to be recalibrated with all new cell cultures or media.

IRUBIS is a small startup without a brand name, and you’re up against measuring instrument multinationals everyone in the biotech industry knows. How can you compete with them?

With a laser-sharp focus on one application. If we look at spectroscopy, the instruments available on the market are built for multiple industries. They have several disadvantages when used in bioprocessing. We’ve visited several companies where expensive measuring instruments gather dust in a corner of the lab. When we ask people why they don’t use them, they tell us these devices are too cumbersome and complex for the task at hand. What we lack in size as a startup we can more than make up with speed and by being very attentive to the needs of our customers.

You need to build a sales team though, and good technical salespeople are rare.

We’re hiring and we’re growing our team, that’s correct. Hiring is always a challenge but we’re confident that we can offer a very exciting job for people who have a degree in biotechnology with a high interest in sales. We’re not cold calling potential customers, we’re planning projects together with clients that we know from conferences or contacted via LinkedIn. Our salespeople get to visit plenty of different customers and labs, get to know their processes and how our device Monipa can best be implemented. The advantage we have as a company is that a typical customer doesn’t just have one or two bioreactors, some have hundreds in several countries across the world. We start with a demonstration and once this is successful, the potential for expanding to different sites of a client is substantial. It happens that we start with an upstream project and then the people talk to their downstream colleagues that they should have a closer look at our solution.

Selling is but one challenge for a startup. You also need to scale production and assure maintenance.

At the moment, the assembly is in house, and we print our flow cells ourselves. We have the option to outsource production at one point or keep it in-house to ensure quality and have the ability to iterate fast. As for servicing, this has worked well remotely with our current projects. This too will evolve over time as we scale up the company.

As you mentioned, bioreactors are spread all over the world. How will IRUBIS expand geographically?

Now our focus is clearly on Europe, although we have projects in other countries since our customers have a global footprint. We’re working together with a distributor in Asia. We already made the first steps towards the important US market. We have been to the US already twice this year for a conference and demo projects. A Monipa 1 system is currently tested by a customer in the US. So, the next big step in the future will be the expansion to the US, which is the biggest market worldwide. We’re excited about the challenges and opportunities that lie ahead.

Written by

WITH US, YOU CANCO-INVEST IN DEEP TECH STARTUPS

Verve's investor network

With annual investments of EUR 60-70 mio, we belong to the top 10% most active startup investors in Europe. We therefore get you into competitive financing rounds alongside other world-class venture capital funds.

We empower you to build your individual portfolio.

More News

28.06.2022

Sympatient is building the first digital anxiety clinic

When startups want to raise money, they can choose between different options. The most commonly used instrument is equity, but other sources of financing such as debt, grants, SAFEs and convertible loans are frequent, too. This article explains what investors need to know about convertible loans, the most common financing form besides equity.

22.06.2022

A new approach to replacing animal testing

Governments and companies around the world invest heavily in non-animal testing systems that provide insights into the harmfulness of chemicals and diseases affecting humans. Startup Nagi Bioscience will soon start commercializing an automated device that promises to speed up science. In this interview, co-founder Matteo Cornaglia explains how it works.

12.05.2022

“Our mission is to set the standard for children’s nutrition”

In one year, the number of stores stocking yamo’s baby and child food products went up from 100 to 3200. In addition to Coop in Switzerland or dm in Germany, they are now available at big retailers like Carrefour Spain and Continente Portugal. Co-Founder and CEO Tobias Gunzenhauser talks about his ambitions of making yamo the leading children's food brand in Europe and the importance of fostering a community of like-minded people around it.

Startups,Innovation andVenture Capital

Sign up to receive our weekly newsletter and learn about investing in technologies that are changing the world.