ANYbotics, the Swiss robotics powerhouse, is ready to scale globally and create a workforce of autonomous robots for industrial inspection. In our interview, founder Péter Fankhauser emphasizes that its versatile four-legged robots solve a critical data problem for large industrial clients. He also offers a glimpse of the future of physical AI.

Co-Founder & CEO, ANYbotics

Péter Fankhauser co-founded ANYbotics in 2016 as a spin-off from the ETH Zurich Robotic Systems Lab. The company was incubated in Wyss Zurich. ANYbotics’ AI-driven autonomous four-legged robots automate regular inspections in industrial and hazardous environments. The company has raised more than USD 130m so far.

Péter has a Ph.D. in Robotics from ETH Zurich .

ANYbotics emerged in 2016 as a spin-off from the prestigious Robotics Systems Lab at ETH Zurich. The founding team consisted of Samuel Bachmann, Remo Diethelm, Péter Fankhauser, Hanspeter Fässler, Christian Gehring, Marco Hutter, Andreas Lauber, and Roland Siegwart. Starting as a Wyss Zurich project, the team quickly expanded and recorded its first sales in 2017. Financial backing has been crucial to ANYbotics’ expansion. Since its inception, it has raised more than USD 130m, which has enabled the company to grow to around 200 employees by early 2025, with offices in Zurich and San Francisco.

ANYbotics specializes in developing autonomous legged robots designed for industrial applications. Their flagship product, ANYmal, represents a breakthrough in robotic technology. It is capable of performing complex industrial inspections and condition monitoring tasks. The robot can navigate challenging environments, including stairs, cramped spaces, and rugged terrain. It is equipped with multi-modal sensors that collect visual, thermal, acoustic, and gas data. The ANYmal X, a special version of the robot for safe use in explosive atmospheres, will start customer deliveries soon.

The company’s primary mission is to transform industrial operations by addressing critical challenges such as labor shortages, worker safety, and operational efficiency. ANYbotics’ robots are designed to take over dangerous, repetitive, and challenging tasks, providing real-time data interpretation and enabling more informed decision-making in industries like energy, power, metals, mining, and chemicals.

Their technological approach combines advanced autonomous operation with artificial intelligence, allowing their robots to navigate complex industrial environments without traditional navigation markers or GPS. This unique capability has earned ANYbotics significant recognition, including the IEEE Robotics and Automation Award for Product Innovation in 2022.

One of ANYbotics’ clients baptized their new inspection robot “Roberta”. Are ANYmals female?

Our robots don’t have a gender. Others have given them male or pet names. One client team has even built a small doghouse for their ANYmal. We like that because it shows they care. On-site workers can be skeptical before they have a chance to interact with our robot. With new customers, even though it is an autonomous robot, we allow their employees to steer it first and get a feeling for how it walks and reacts, for example, by slowing down or stopping before an obstacle. This gives them confidence. They quickly warm up to it and realize that it came to help. They treat it kindly, like a new team member, and giving it a name expressing that.

That’s cute. But your clients, who are large companies, think about the return on investment of machines, not their cuteness factor. Why do they spend money on ANYmals?

Our clients think about how to run their large plants and installations optimally. They want to minimize downtime, which costs them hundreds of thousands per day. They also want to minimize surprises, so their employees, usually highly sought-after and skilled production engineers, inspect parts of the plant by performing inspection rounds multiple times a day. The plant owners use sensors and IoT as much as technology permits, but they still need humans for a majority of inspection tasks. In some environments, think high voltage, you need to shut down parts of the installation for humans to pass. Other environments are dangerous or at least uncomfortable for humans, imagine gas leaks or high temperatures. We complement human capabilities with robotic ones to ensure plant safety and highly reliable data collection.

Other companies, such as Unitree from China, manufacture similar-looking legged robots at very cheap prices. Has ANYbotics fallen into the typically Swiss trap of over-engineering and making products that are too expensive for what they do?

More companies can build a robot with four legs; this is true. But our clients don’t want to buy a robot to play around; they don’t have a robot problem, they have a data problem. Our autonomous robot is just a tool to gather data. We provide a full-stack solution that integrates software and a certified robotic platform. Recently, ANYbotics launched Data Navigator, a software platform that harnesses the full potential of inspection data by contextualizing and analyzing it. Our customers can start solving their inspection data problems from day one. We’re not aiming to become a low-cost player. However, streamlining the design of the robot and its bill of materials is a constant duty for us. In the future, we’ll maybe produce it in several locations, not just Switzerland, to stay cost-competitive.

Switzerland excels in robotics, and the Robotics Systems Lab at ETH Zurich is a talent factory for founders. What makes it successful in creating spin-offs?

A general advantage of Switzerland as a country in robotics is its broad mechanical engineering industry. We have two centuries of tradition in this field, many people who understand how to build things and are passionate about it, and an apprenticeship system that produces excellent mechatronics specialists. It helps that large companies such as Siemens and ABB have R&D centers in Switzerland. Both ETH Zurich and EPFL have outstanding professorships in Computer Science and AI, which is also crucial for robotics. Finally, a generation of Professors like Roland Siegwart and Rafaello D’Andrea have firmly anchored the spirit of entrepreneurship in students’ minds. Also, the pioneering drone startup Flyability in Lausanne has inspired many founders and served as an example of what is possible. For me, robotics is a perfect field because you can create many exciting new things. I wouldn’t want to spend my life trying to improve the efficiency of a combustion engine by another percent.

Artificial intelligence is seen as a game changer when it comes to improving the efficiency and cleverness of robots. Robots are even called “physical AI” now. Where is the truth, and what is just hype?

ANYmals don’t follow a fixed programmed routine. They learn by themselves, based on a set of criteria, how to move and react to a changing environment. This is called reinforcement learning. Much pioneering work was done in this field at ETH Zurich ages ago, before people discovered ChatGPT. We have integrated deep reinforcement learning into our robots since five years ago. More and more people can do this, but we have the advantage of working with our models and tons of data gathered by a growing fleet of robots that can learn from each other by simply updating their software. We have made drastic improvements in how our robots perceive their environments, how we can ensure localisation even if no GPS is available, and how we can ensure data quality, for example, by ensuring that readings captured by the camera are legible. As for physical AI, I am sure that robots will learn how to interact with their environment and be able to, say, reliably flip a lever very soon.

Can’t you simply mount a robotic arm on an ANYmal?

Yes we can, and for research purposes we already provide this In the context of an R&D lab, you can achieve all kinds of cool things. But in an industrial environment, you need absolute reliability. Manipulating objects is often easy for humans. You don’t get deterred if a lever is a bit rusty or looks different from another. However, for robots, the contextual change is much higher. Generalized manipulation is an unsolved problem in robotics.

You said your clients need things inspected; they don’t need a robotic arm.

The ability to open a control cabinet, for example, would open new use cases for the same client base. In the chemical industry, we could fill samples from tanks in flasks. These tasks are tedious and time-consuming for humans; sometimes, they must be even done in protective suits.

Speaking of hazardous environments, the upcoming ANYmal X is certified to operate in zones where flammable gases are likely to occur. These zones are found in chemical or oil and gas plants. How do you ensure that a complex moving electrical device like ANYmal doesn’t create a spark and risks an explosion?

Ex-proofing a device is, as you can imagine, a significant challenge since we can’t just wrap the robot up in a cover. We had to develop several innovations, including specialized batteries, patented motor design, and a pressurized body filled with nitrogen. We have already received a lot of interest and pre-orders from the industry for ANYmal X because it solves a significant gap in the market.

With robots, people also fear other risks. What about the scenario of hacker-controlled robots wreaking havoc on an industrial plant?

Cybersecurity is an important topic for a reason. Critical infrastructure like large electricity plants are in the crosshairs of malevolent actors. As a result, the requirements regarding cybersecurity are high, which necessitates significant investments in these capabilities from our part to satisfy them. We design our systems so customers stay in full control of their data and everything is isolated by design, with hardened attack surfaces and transparent security practices that our customers can rely on.

ANYbotics sells robots. However, a robot can only be sold once, and investors like stable, recurring revenues. Can ANYbotics offer robots as a service?

Yes, we already do. We often jokingly say that ANYbotics has 400 employees, 200 of them are human. We are responsible for all of them. And again, our clients often don’t want to buy or own something; they want a job to be done, similar to their human employees. I would not be surprised if companies in the future add RR responsibilities to their HR team, with RR, robotic resources, being responsible for choosing, hiring, and managing the robots needed for the tasks at hand. In the meantime, we offer robots-as-a-service together with financing partners. For our clients, this means predictable costs, and for ANYbotics, recurring revenues.

When I imagine a robot resource manager interviewing a robot for a job, the robot looks humanoid, not four-legged. Four legs good, two legs bad?

I don’t think the humanoid shape will be the dominant form factor for all robotics. A bird and an elephant are good at different things, as are a tractor and a Formula 1 car. ANYbotics’s vision is to design robotic hardware and software that excels at specific tasks. This vision includes neither solely legs nor that it has to be four. If wheels are better, we’ll use wheels. If we need to climb walls, it might be magnets. The ANYmal’s legs and size result from the size and strength required to climb stairs. For other tasks, our robots will look differently.

Still, Boston Dynamics is betting heavily on its humanoid Atlas platform and recently gave it a full-electric upgrade.

Our robots are built to withstand rough industrial environments, are dust- and water-proof and impact-protected. Boston Dynamics’ robots are not. We offer an end-to-end solution that integrates seamlessly with digital maintenance management tools and digital twins. Other providers just sell hardware and basic software. They leave their clients to figure out how to integrate it, which leads to patchwork solutions. Our typical customers don’t have time or the skills for this.

Whatever their form, what will the future bring for robots?

They will become better at interpreting humans and gaining their trust. As humans, we trust people whose behavior follows predictable patterns. Robots will understand their environment better than seeing just a geometry, which will make human-robot interaction more natural. We will get used to seeing robots much more and take them for granted. In San Francisco, no one turns their heads anymore when a self-driving Waymo passes by in the street. We will also stop calling robots robots and give them more precise names. You also don’t call your dishwasher a robot, even though technically it is. We’re also conscious of our responsibility as a leading provider of advanced mobile robotics. This is why ANYbotics and other leading companies in the field have signed a pledge not to support the weaponization of our robots. We’ll carefully review potential customers and develop technical features to mitigate the risk of weaponization. This is something many of our employees, customers, and investors care about.

You raised 60 million dollars in December 2024, bringing total funding to more than 130 million. What will you use that money for?

We are scaling globally. We have partners who will help us internationalize, such as SLB, Equans, Siemens Energy, and Kanadevia Inova. These partners are much more than mere distributors. They are leading industry providers, and we are their preferred ground robot supplier. As for our production, we have outsourced it to our partner Zollner, a company with a global footprint that can ensure rapid production scaling to more than 1,000 units annually.

With a fleet of two hundred robots, ANYbotics has barely scratched the surface of its target market. There are thousands of power and oil and gas plants globally and tens of thousands of chemical, mining, and metal plants. What is your ambition?

We are creating a workforce of autonomous robots for industrial inspection. As you say, we haven’t reached even 1% of what is possible regarding expansion. Some of our clients have hundreds of plants, and we’ll equip them with robots to do dangerous and tedious work to ensure their plants are up and running. We are building a global company, and our second office in San Francisco is just a start. We will create a large and profitable business while staying at the forefront of cutting-edge robotic technology, exploring other applications and robot types.

Written by

WITH US, YOU CANCO-INVEST IN DEEP TECH STARTUPS

Verve's investor network

With annual investments of EUR 60-70 mio, we belong to the top 10% most active startup investors in Europe. We therefore get you into competitive financing rounds alongside other world-class venture capital funds.

We empower you to build your individual portfolio.

More News

03.02.2025

“Scrona’s printheads are ready for high-volume production.”

It started with a world record and is now changing how electronics are manufactured: Scrona manufactures some of the most advanced printheads worldwide in a clean room in Zurich. CEO Patrick Heissler talks about leading the ETH spin-off into the industrialization phase in this interview.

12.01.2023

Why a new generation of chips are needed for AI

AI models rely on the quick processing of massive amounts of data that classical computing circuits were just not designed for. Professor Luca Benini of ETH Zurich tells us why it's urgent to tackle this challenge and how Dutch startup Axelera is aiming to solve it.

11.03.2022

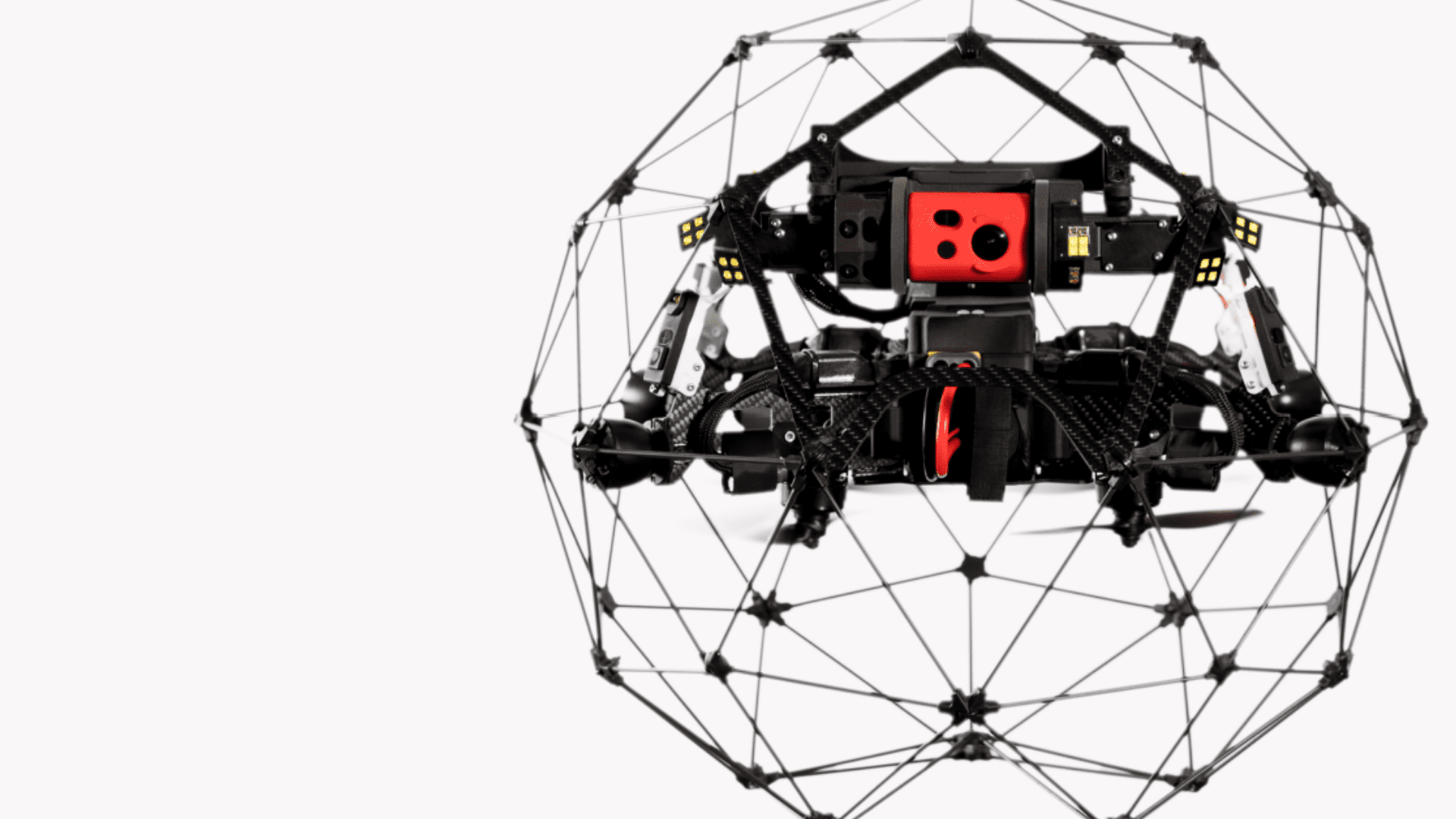

Flyability: market leader for indoor inspection drones targets CHF 20m in revenues

Removing humans from dangerous industrial jobs by using drones for inspections saves plant owners a lot of money. Lausanne-based drone manufactuerer Flyability is the leader in this field. In this interview Co-founder Patrick Thévoz talks about the vast potential of the market.

Startups,Innovation andVenture Capital

Sign up to receive our weekly newsletter and learn about investing in technologies that are changing the world.