ETH spin-off Scrona just announced a Series A financing round of USD 9.6 million. With a printhead that has 100x higher resolution than the competition, the startup will reinvent micromanufacturing in a wide range of industries. In this interview, CEO Patrick Galliker explains how.

Co-founder and CEO, Scrona

Patrick Galliker, Martin Schmid and Julian Schneider developed an inkjet process with a resolution 1000 times as high as conventional machines while still attending university. They founded Scrona in 2014. Patrick has a Ph.D. in Nanosciences from ETH Zurich.

You co-founded Scrona in 2014. What were you doing before that?

I was doing a PhD at the Mechanical Engineering Department at the ETH Zürich. My PhD was on the technology that we are now about to commercialise. I was hired to work on a project on printing technology; specifically, on developing a way to eject liquid onto a substrate from a nozzle at a very high resolution. Some work had already been done at the laboratory by my predecessors, but it was far from being understood. We found that the technology really has a lot of potential.

How did you meet Scrona’s other two co-founders, Julian Schneider and Martin Schmid?

Julian, who is now our CTO, was working on the project at the ETH with me. Martin, our CIO, had been hired by our predecessor at ETH to create software for the printing system developed at the lab. He was actually working on the technology before Julian and me, just from a different angle. The three of us decided to join forces. Developing the technology always requires different angles; in our case: microfabrication, hardware development, electronics development and, of course, software. The three of us had all these skills.

What value does your technology offer customers?

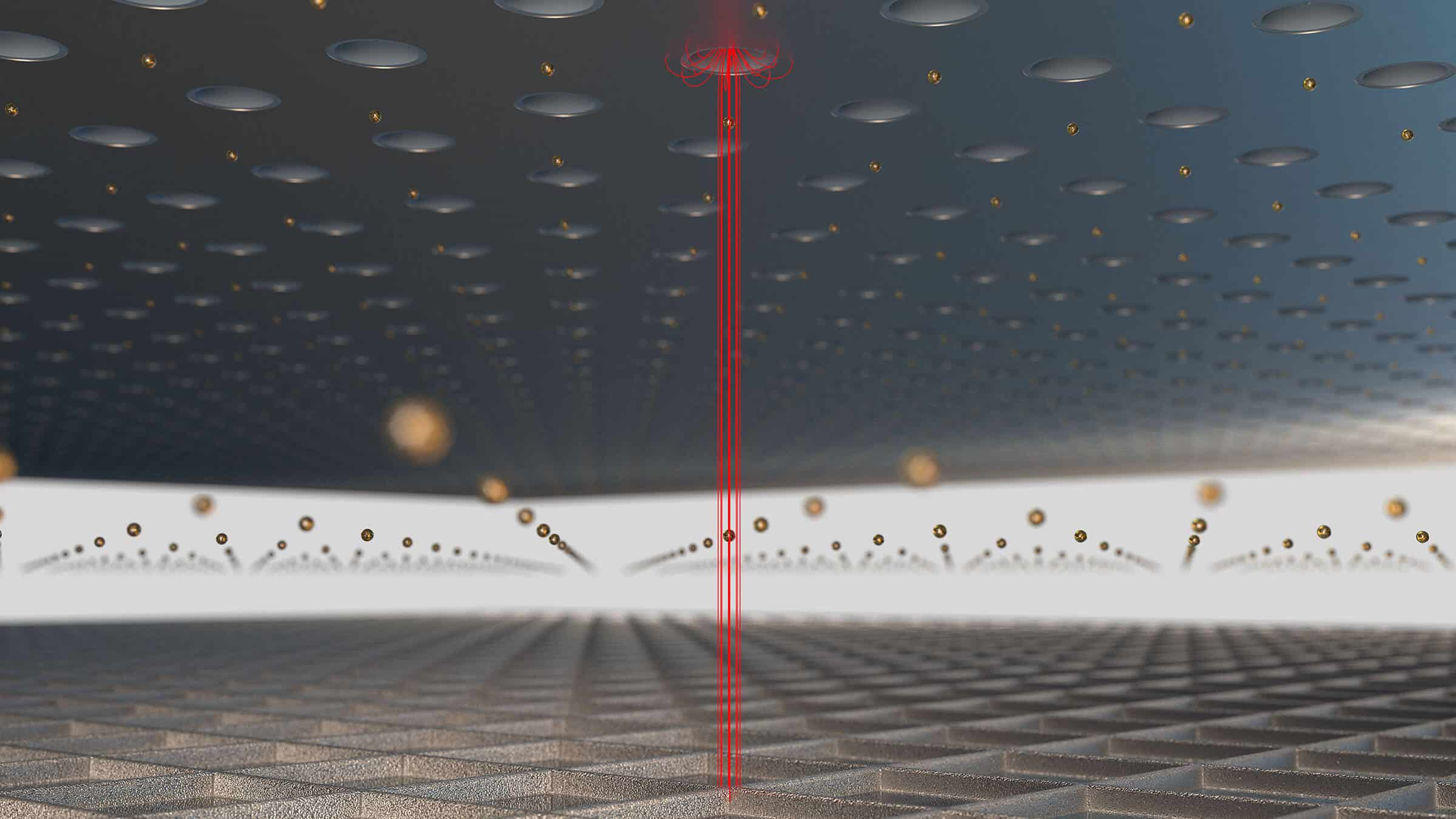

The printheads that we developed – our core product, which defines what a printer can actually do – have two main USPs on the technical side, plus an additional USP that also distinguishes them from current inkjet printers. Firstly, we can print at a substantially higher resolution. Secondly, our printheads have a much higher material compatibility; they are much more flexible when it comes to the ink. Thirdly, we can adapt our printheads to the customer environment, which inkjet printers cannot do.

What are some of the potential applications?

Our printheads’ high-resolution capability lines up with some emerging markets in printing technology where high resolution is a must. One core application is display technology. Inkjet printing is already present for very low-end manufacturing tasks in this area, but one of manufacturers’ strategic goals for the coming years is to increase the amount of printing technologies used to manufacture displays. Additive-manufacturing technology has the potential to reduce the cost and complexity of manufacturing, which is needed for display to become more abundant and cheaper. Other markets include semiconductors; the so-called backend, rather than the frontend. Very high-resolution wiring is needed on the chips to connect them with each other. Manufacturers are looking at the interconnectability between chips and seeking to make this affordable. This is where Scrona can enter with its technology.

What about the second USP, relating to the choice of inks?

This very much aligns with existing markets, in which the customers are already able to manufacture their products, but where the current environment is just not flexible enough for business customers. They actually spend much more money on the ink than on the inkheads, because the inks need to engineered to cope with the inkjet printers’ narrow bandwidth. With our printheads, they can use much cheaper inks, enabling them to cut costs. Another application is additive manufacturing in the traditional sense, like 3D printing. At its core, our technology has a fundamental advantage over inkjet printing. I believe that, at some point in this future, this technology – which is called electrohydrodynamics – will replace inkjet printing completely.

Invest in Startups

As one of Europe’s most active venture capital investors, we grant qualified private investors access to top-tier European startups. With investments starting at EUR/CHF 10’000, you can build your own tailored portfolio over time and diversify across stages and sectors.

What did Scrona choose to focus on and why?

We chose to take a step back and only focus on the core technology: the printhead. Our printheads do not care whether they are used in a graphical environment or in the display market. Bringing them from one market to another is pretty simple from a technological point of view. It gets more complicated when it comes to marketing it all: having access to the market, building a whole ecosystem, and so on. Applying our printheads to a specific environment involves a considerable amount of time and knowledge. Instead of doing this ourselves, we foster partnerships. Our partners already have the market access and the complementary technology; that is, the printing system. This means that we do not have to limit ourselves to a single application.

How can Scrona’s ultrahigh-resolution printing technology break today’s manufacturing paradigm?

Today, especially in the high-resolution field, manufacturing is done in a way that most people do not know about: microfabrication. This works in a way somewhat like additive manufacturing, layer by layer. The problem is that each layer has many subprocesses and that the machines required have a very high cost burden. In microfabrication, depreciation – the cost of machines – is much higher than in many other industries. In contrast, printing technologies put more of the cost burden on the variable-cost side and generally reduce the fixed costs. This can be considered a change of paradigm, because you can replace tens of machines with a single one, and use fewer material and energy resources.

Can this be considered revolutionary?

We will not replace the whole microfabrication market, but in those areas where we do, it will definitely be a revolution. A director at a big Korean company once told me that what we are doing is industry-changing. I think so, too. If it is properly commercialised, our technology is truly revolutionary.

Competitive additive manufacturing is usually either precise- or fast. How does Scrona combine precision and speed, distinguishing itself from its competitors?

Our printheads combine the precision of electrohydrodynamics with speed by having more than one nozzle. Certain other companies use electrohydrodynamics, but they have no way of making it fast. They do not have a printhead with more than a single nozzle. We do – and that makes us fast. If we have a thousand nozzles on our printhead, we are a thousand times faster than those companies. If we have ten thousand nozzles, which is where we want to go, we are ten thousand times faster. Some companies already have inkjet printers with a thousand or ten thousand nozzles, which makes them fast, but they lack precision.

What industries could benefit from Scrona’s technology?

The display industry will definitely start profiting from our technology very early on. It has things on its roadmap that cannot be achieved with inkjet printing, so it will need our technology. This will have major benefits for manufacturers, but consumers may not see the difference yet, except perhaps for slightly lower prices. Yet as the technology matures and display manufacturers learn to use it, it could have a tremendous effect. For you as a consumer, it could enter every part of your life as displays become increasing widespread. For example, in the automotive industry, every car manufacturer would like to have more displays in their cars. This will certainly be one of the biggest applications for display companies in the future. Other applications include housing and appliances.

Scrona holds a Guinness World Record for the smallest inkjet-printed colour image. What is its significance?

It is an image that could fit on the diameter of a single hair – not something you need every day, but it is highly significant from a technological perspective. With the image, we provided a glimpse of how our technology can be used; for example, in the display field. We received many responses to the image, especially from the display field.

What is your approach to the commercial side of things?

We see ourselves very much as a technology company. We have the model to really focus on our core IP; we want to be innovative and ensure that our product fits our customers’ requirements. From a commercial point of view, we try to do as little as possible. Instead, we build partnerships with big, powerful companies that have market access to bring this technology to the user base. Together, we work to integrate our printheads into their systems, which they then sell. The users cannot just buy our printheads from another manufacturer, so every system placed in the market will directly lead to demand for them.

What are your goals for the year ahead?

Firstly, demonstration. We are building a demonstration lab where we can use our own printheads to demonstrate certain applications, which will help explain the benefits of our technology to the broad public. For example, we would really like to print a full touch screen using our technology. Secondly, we want to build more relationships and to strengthen existing ones. We already have many partnerships, but we want to bring them to the next level. So far, a lot has happened in the lab space. Next year, things will go industrial, so that our partners and clients can actually feel how our technology is changing their production.

Written by

WITH US, YOU CANCO-INVEST IN DEEP TECH STARTUPS

Verve's investor network

With annual investments of EUR 60-70 mio, we belong to the top 10% most active startup investors in Europe. We therefore get you into competitive financing rounds alongside other world-class venture capital funds.

We empower you to build your individual portfolio.

More News

15.02.2022

Scrona raises

USD 9.6m Series A

Scrona AG Raises $9.6M in Series A to revolutionize ultra-high resolution 3d printing for a wide range of industries such as semiconductor and display manufacturing. Industry’s first multi-nozzle printhead that can scale to 0.5 μm for 100X higher resolution and 10X higher throughput than competition will reinvent micromanufacturing.

08.12.2020

3D printing moves beyond prototyping

The hype about consumer 3D printing that was at its height a few years ago has died down. But recent developments have led to advances in the technology and to its adoption in manufacturing functional parts. Aleksander Ciszek, CEO of 3D printing software startup 3YOURMIND explains the reasons why.

06.01.2020

CREAL (display technology): CHF 4.3m Series A

CREAL has raised CHF 4.3 million from Verve Ventures, DAA Capital Partners and private investors. Verve Ventures led the round and contributed CHF 1.8 million.

Startups,Innovation andVenture Capital

Sign up to receive our weekly newsletter and learn about investing in technologies that are changing the world.