The European Union recently approved a ban on new fossil-fuel cars from 2035 and has introduced stricter guidelines for lithium-ion battery recycling. With 30 million electric vehicles expected to hit European roads by 2030, current recycling methods are not up to the task as they fail to recover the most important materials in batteries. tozero has developed a proprietary process that enables the recovery of all critical materials, including lithium. CEO Sarah Fleischer tells us how she teamed up with her co-founder Dr. Ksenija Neumann.

CEO and Co-Founder, tozero

Sarah Fleischer is the CEO and Co-Founder of tozero. She previously worked for the Luxembourg Space Agency, helping to establish a better and more attractive financial ecosystem to attract space ventures to Luxembourg. While there, she helped launch early-stage space venture capital fund, Orbital Ventures and set up the Business Division and Startup Incubator of the European Space Resources Innovation Center. She then joined digital logistics startup Forto leading their commercial strategy and partnerships. Sarah has a Master of Science in Mechanical Engineering and finished her studies at the Harvard Business School. She is also an alumna of the Center for Digital Technology and Management (CDTM) Honors Program.

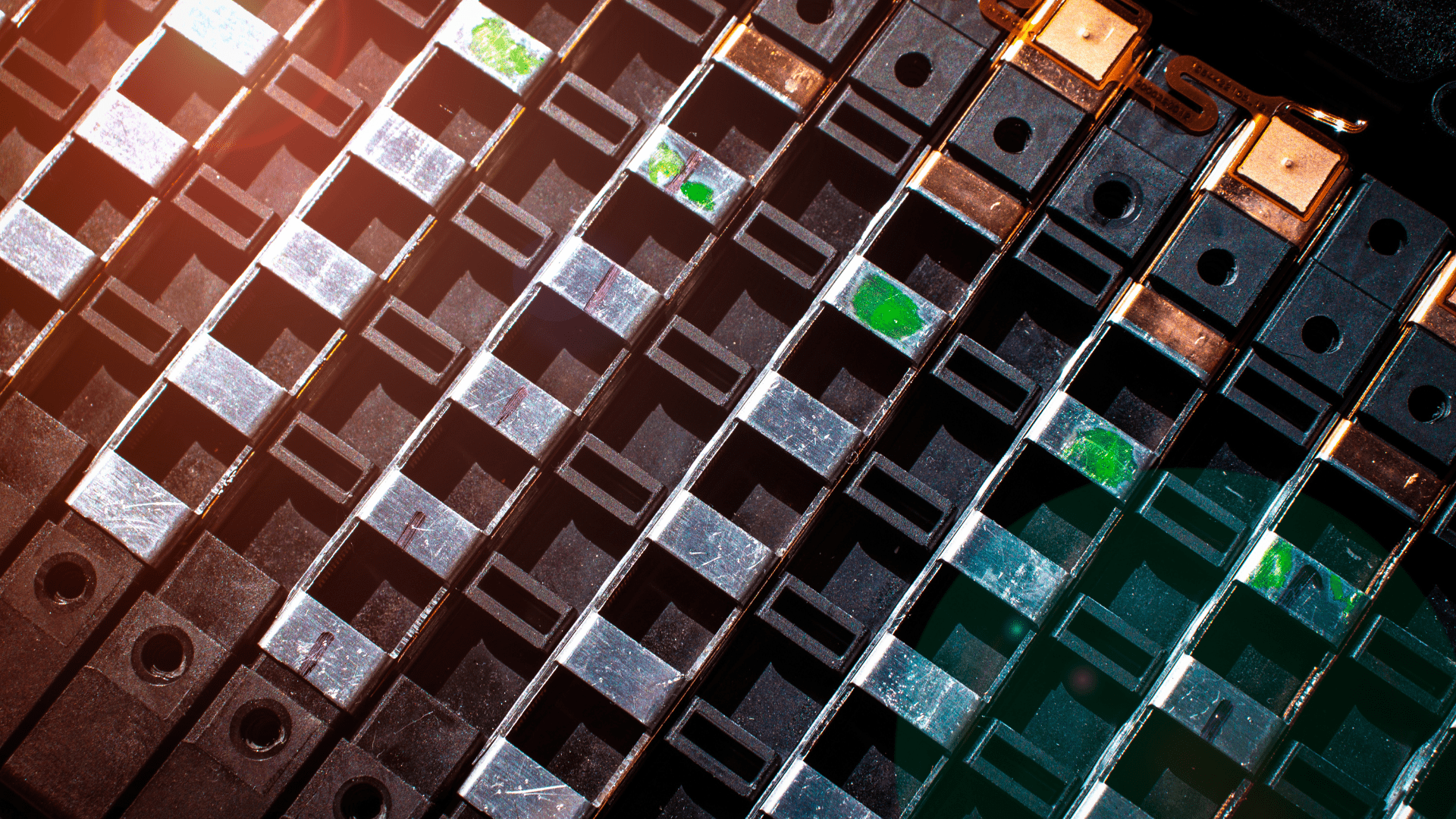

Lithium-ion batteries (LiB) are crucial for our decarbonization efforts and will be used to electrify mobility vehicles, machines, drones and power banks. Between 2020 and 2030 LiB production in Europe is expected to increase twentyfold. However, Europe’s ambition for electrification creates a high dependence on mining countries resulting in precarious supply chains with a high environmental impact and vulnerability to geopolitical tensions. Recycling the 100,000 tons of battery waste expected to be created annually by 2025 is the only way to decrease the environmental footprint of electrification and strengthen the geopolitical position of Europe.

Munich-based startup tozero aims to close the loop of lithium-ion batteries and return raw materials such as lithium, cobalt, nickel back into the market. These materials will be provided as fresh battery-grade materials to battery producers.

tozero has raised €3.5 million in a pre-seed financing round led by Berlin-based Atlantic Labs. Verve Ventures, Possible Ventures, renowned business angels and other founders such as former VW board member Jochem Heizmann and the co-founders of Personio and FINN, have also joined the round.

How did you and your co-founder Ksenija Neumann meet and decide to start tozero?

Four years ago, we were both working in the space industry in Luxembourg. I was at the Luxembourg Space Agency while she was working in a space startup. It’s a very small community so we got to know each other at an after-work meetup of the entire space ecosystem in Luxembourg. On the first evening we met, we immediately clicked and we actually signed a contract on a napkin that we will one day launch a startup together. We stayed in touch afterwards, and now, four years later, we’re finally doing it.

Why did you choose tozero as the project you wanted to collaborate on?

We are both passionate about making a real impact. We wanted to put our time and energy into a company that would be beneficial for society. Luckily, Ksenija is an expert in battery recycling. It’s what she’s been doing in her postdoctoral research at RWTH Aachen, and it happens to be one of the last missing pieces of our electrification era. Because you have all these big electrical vehicles being produced in the automotive industry, but what about the bigger picture? Where do the materials for making batteries come from? What happens with lithium-ion batteries when they’re used up? What is the recovery rate for materials? As a mechanical engineer, I was quite aware of these issues since my studies. When Ksenija and I reconnected a few months ago and realized how slowly the industry is moving to tackle this problem, we decided to take the leap and establish tozero to introduce an immediate solution.

Why are lithium-ion batteries so difficult to recycle right now?

When big companies say they are recycling batteries right now, what they mean is that they’re throwing lithium-ion batteries into a smelter at temperatures of 1400 degrees Celsius. It’s called pyrometallurgy. Using this process, you cannot recover all the critical materials like lithium or graphite that are inside the lithium-ion batteries. Current recycling methods are just highly inefficient and too many materials go to waste. That’s why a new recycling method is needed. New legislation from the European Commission is also making it a legal obligation. Recycling efficiency will need to be increased to 70% by 2030 and there are efforts now to introduce recovery requirements for the critical materials, like 70% for lithium and 95% for nickel and cobalt. By 2030 battery producers will also be required to include recycled materials in all new batteries. Companies therefore will not have a choice, at least here in Europe. A new recycling procedure has to emerge so we can reach these mandatory recycling quotas.

How did tozero manage to crack the problem of efficient lithium-ion battery recycling?

She’s going to hate me for saying this, but it’s Ksenija, she’s just that smart (laughs). Of course, her method is a culmination of years of research at RWTH. Professor Bernd Friedrich who heads the Institute of Metallurgy and Metal Recycling (IME) is a pioneer in battery recycling research and is now also a technical advisor for tozero. He has been spearheading this field for two decades. I think therefore it was a combination of being in the right place and having the brain power to figure it out.

A lot of people are looking into new methods to recycle lithium-ion batteries right now. How does the market look like?

We’re the first European startup dedicated to doing this. We have American and Chinese competition. In Europe, things have started slowly moving along as well. The big companies that have been recycling using the old methods, where you cannot recover all the critical materials, have to shift now, especially because of the legislation, towards closing the loop and recovering all the materials. They are all in the race, but they’re just getting started. And while yes, they do have a lot of money, they also have a long way to go. They’re still just trying to figure out how it works and doing their lab tests. The company that can process the highest throughput while also maintaining high efficiency rates in the recovery will become the leader of the market. As things stand now, I would say there’s a good chance it will be us.

Invest in Startups

As one of Europe’s most active venture capital investors, we grant qualified private investors access to top-tier European startups. With investments starting at EUR/CHF 10’000, you can build your own tailored portfolio over time and diversify across stages and sectors.

Have these American and Chinese companies also found the missing piece of the puzzle? Can they also recover critical materials like lithium?

This is very difficult to assess. Because if you want to try and buy lithium from them, no one is selling it. This is the biggest problem in this industry. There are lots of claims, a lot of press releases, a lot of talk of capacities and so on. But if you were to look into it, you’d find that no one has gotten that far yet. Everyone is preparing to build their first plants. No one has made it to the industrial scale yet. We believe the market is going to be huge though. It’s not a winner takes all market. I think there is a lot of room for many recyclers, even next to us, on the European market.

Where will you get your battery supply?

We are in discussions to cooperate directly with the original equipment manufacturers (OEMs), but also battery producers. They have to collect all their used batteries so we can get them directly from them. Scooter companies are currently having problems with their batteries as well. They only last a few years and because it’s difficult to export e-waste at the moment due to European Commission regulations, they’re just being stored in containers throughout Europe. I think supply of batteries will definitely not be an issue.

You decided to announce the company only after the pre-seed round was closed. Why did you choose to begin in stealth mode?

There were two main reasons behind this. One was that we decided from the beginning we didn’t want to make any claims without solid results behind them. That’s a matter of principle for us. Secondly, you have all these big companies researching new recycling methods and they would love to look into our technology. We didn’t want to draw their attention this early so starting out in stealth helped us protect our intellectual property.

I believe that when great companies are built, if they follow a great vision and serve a purpose in this world, it will get through to investors regardless of the economic climate.

Despite starting out in stealth mode, tozero quickly became one of the most talked about startups in Germany. How did you manage to generate so much interest?

A lot of people told me not to do the startup, not to fundraise because of the market situation. And my answer was always the same: I don’t care about the market situation. I believe that when great companies are built, if they follow a great vision and serve a purpose in this world, it will get through to investors regardless of the economic climate. I think we’re also very lucky that the timing is right, in the sense that there is a growing awareness of sustainability. I don’t believe we could have done this five years ago. I think climate tech, clean tech, decarbonization, circular economy, all these kinds of topics are very much on people’s minds right now. We came in at the right time with the right idea. We closed the financing round in three weeks, we raised €3.5 million and we were massively oversubscribed.

In practical terms though, how did you manage to reach prominent business angels like former VW board member Jochem Heizmann?

One of the things that helped us is that I am an alumna of the Center for Digital Technology and Management (CDTM) honors program from the Technical University of Munich. A lot of famous German unicorns have come out of CDTM: Personio, Forto, Trade Republic. One of yuri gravity’s co-founders, Mark Kugel, was also part of the program. I think the CDTM network is very helpful, to exchange experiences with other founders, to learn from their mistakes and successes, how they approach things. It’s also a good entry point into the investment world.

What are the biggest challenges when scaling up this kind of technology?

Recycling lithium-ion batteries involves a lot of dangerous processes and chemicals. Safety measures therefore have to be very tight. This industry is prone to workplace accidents. My number one priority for tozero is that everybody who works in our plants is safe. Another challenge is scaling up the process itself. At small scale, you have a very secure environment and all the variables and the interactions between the materials are controllable. Once you scale up, you have outside influences, and it becomes harder to control reactions.

You’ve already started working on opening your first plant. At what stage is the project?

That’s our next milestone: to finalize the plant and do a technical scale up of our technology. We want to prove that we have the capacity to recycle much larger quantities of batteries. We want to show ourselves, our investors, but also the industry that our technology is scalable. I think that’s the breaking point and it’s going to be a big success.

Written by

WITH US, YOU CANCO-INVEST IN DEEP TECH STARTUPS

Verve's investor network

With annual investments of EUR 60-70 mio, we belong to the top 10% most active startup investors in Europe. We therefore get you into competitive financing rounds alongside other world-class venture capital funds.

We empower you to build your individual portfolio.

More News

07.09.2022

ClimateTech startup tozero raises €3.5m in funding

ClimateTech startup tozero raises €3.5m in funding as the first European startup to recycle lithium-ion batteries. The pre-seed round was led by Atlantic Labs. Verve Ventures, Possible Ventures, renowned business angels, serial founders and a former VW board member aslo joined the round. tozero introduces a novel process to recover critical materials such as lithium, nickel and cobalt from lithium-ion batteries.

01.06.2022

“Agrivoltaics has become a megatrend”

Europe needs intelligent solutions to decrease its energy dependence. One innovative way is agrivoltaics. Instead of covering agricultural surfaces with plastic tunnels and greenhouses, startup Insolight proposes translucent solar panels. The company is now starting to build its first large-scale projects. Co-founder Laurent Coulot tells us the full story.

30.03.2022

Coffee-to-go without mountains of waste

kooky has developed a system of reusable cups combined with IoT technology. But the key to replacing disposable cups is a system that balances the interests of all stakeholders, explain co-founders Torge Barkholtz and Maximilian Zott.

Startups,Innovation andVenture Capital

Sign up to receive our weekly newsletter and learn about investing in technologies that are changing the world.