It started with a world record and is now changing how electronics are manufactured: Scrona manufactures some of the most advanced printheads worldwide in a clean room in Zurich. CEO Patrick Heissler talks about leading the ETH spin-off into the industrialization phase in this interview.

CEO, Scrona

Patrick Heissler joined Scrona as CEO in 2024. He previously was the Chief Commercial Officer at Focuslight Technologies. He successfully carved out SUSS MicroOptics SA (SMO) from SUSS MicroTec SE, serving as the Chief Strategy Officer at SMO. He successfully built and led the micro-optics materials business at DELO Industrial Adhesives during his tenure.

Patrick Heissler earned his doctorate in physics from the Max Planck Institute of Quantum Optics, which included research stays at the University of Utah and Los Alamos National Laboratory. He also holds an MBA in Innovation and Business Creation from the Technical University of Munich, with modules completed at the Haas School of Business at the University of California, Berkeley.

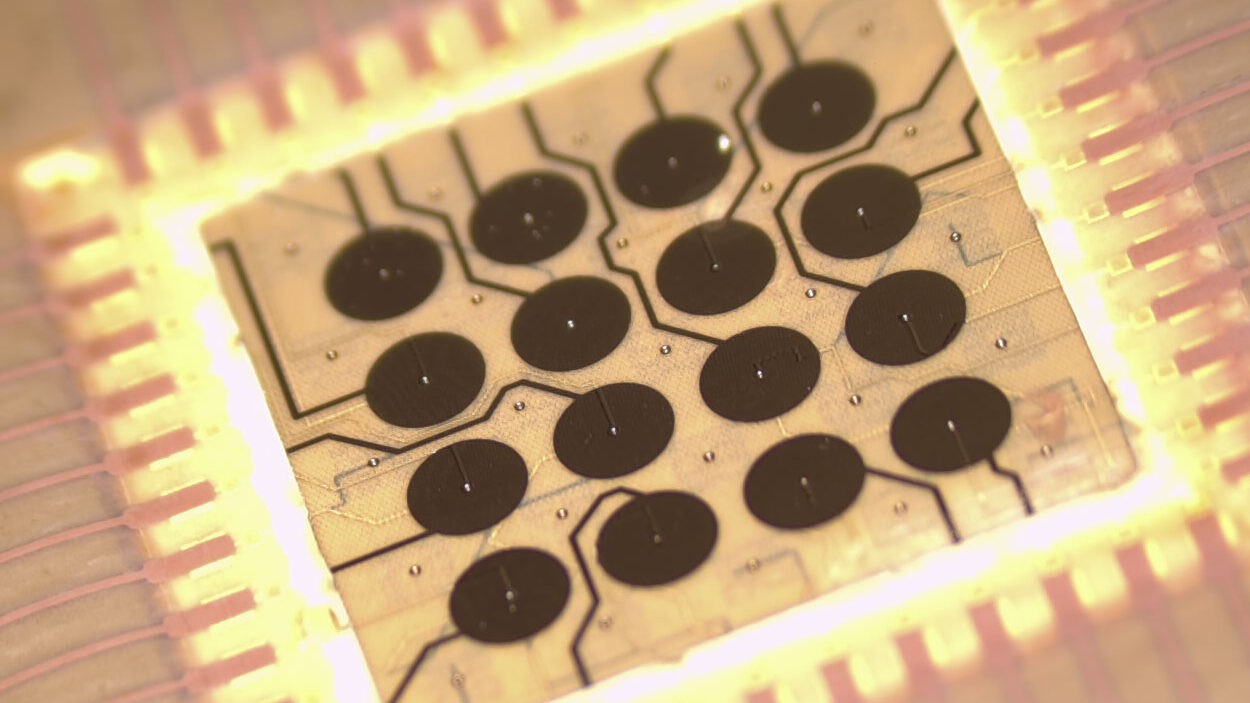

Scrona, an ETH Zurich spin-off founded in 2014, is a forerunner in a technology that will change how semiconductors, consumer electronics and displays will be manufactured. Electrohydrodynamic printing (EHD) uses electrical forces to deposit tiny droplets of almost any material with sub-micrometer precision. The company recently demonstrated its new 128-nozzle printhead at the Consumer Electronics Show in Las Vegas. Verve Ventures has backed Scrona since its Seed round in 2018.

You have a Ph.D. in Physics and a track record as an executive in high-tech industries. Why choose the startup world instead of working for a big company?

Throughout my education and career, I was always close to the practical application of cutting-edge technology. Working in different countries taught me the importance of building international networks and partnerships. I like to work in organizations that achieve maximum impact with minimal resources and bring new technologies to the market. There is a unique combination of high energy and ambition with a grand vision in startups, and that is where I thrive.

Why did you choose Scrona?

Scrona’s technology is exciting; it will transform several industries. The team is very lean and combines a lot of expertise. My skills and network are complementary; we fit together like puzzle pieces. It is also a fascinating time for the company, as the technology is de-risked and we gear up to roll out a reliable product. Securing Europe’s competitiveness in micromanufacturing know-how is also necessary.

Scrona’s technology can manufacture tiny things; you even have a Guinness record for the most miniature color image. But what industrial problem can you solve with your technology?

As you know, the devices that surround us, all the smartwatches and phones, pack increasingly more power in a small space. This has created tremendous value for investors, companies and society at large. However, even the most advanced manufacturing technologies on the micrometer scale currently limit what is possible. For the next evolutionary step of these devices, they aren’t precise enough or too complex and polluting to work at scale. Subtractive manufacturing methods use large amounts of chemicals and water. This is where Scrona comes into the picture. With us, our customers can completely rethink what is possible with printing.

What is?

I’ll give you a few examples. Scrona can print the electrical connections between chips since we can print with conductive materials. We can print fragile antenna structures on sensitive surfaces, such as plastic substrates, which are used for localization services. A third large application field is flexible electronics; we can print on flexible circuit boards. We can even print 3D on top of existing structures.

If you look at this from a more general perspective, our technology is firmly embedded in many megatrends, miniaturization, digitalization, energy transition and energy efficiency. It has also dawned on us that microelectronics manufacturing capabilities are a strategic asset of geopolitical importance. We are leading in this field in Europe and must build upon our advantage.

There are other companies active in electrohydrodynamic printing. What sets Scrona apart from them?

The concept of EHD has been indeed known for years. Scrona’s crucial innovation lies in integrating the technology into a MEMS system, a semiconductor component. This has allowed us to scale the number of nozzles from 8 to 128 in only a few months and will allow us to go even further. Scrona’s printheads are ready for high-volume production and we run our production line here in Zurich.

You just returned from the Consumer Electronics Show in Las Vegas, where you presented the new 128-nozzle printhead to customers. What was their reaction?

They were enthusiastic about it. We have talked about scalability in the past. Many companies have watched what we do and waited for the proof. Now, we have delivered the result. Next to the printhead, we showed a flawlessly printed picture with better than 10 micrometers in resolution. For reference, human hair is 100 micrometers across. Showing this printhead that is ready for industrial use was a significant milestone in Scrona’s journey.

What happens now until the first things are produced with such a printhead?

We work within a greater ecosystem and have agreements with several material and equipment providers. We do feasibility testing for our customers in our application lab in Zurich. Then we supply integration kits to use the printheads to machine manufacturers and they will make their machines available to large producers in the semiconductor industry. To accelerate this process, we often work with many players along the full value chain.

How long does that take?

The qualification time depends on the industry and the application. Consumer electronics can take 6 to 12 months, while semiconductor manufacturing takes longer.

Does that mean it still takes some time, but once your technology is integrated into major production lines, Scrona’s sales can become significant?

We can cross the barrier of CHF 100m turnover in four years. Our sales depend on the number of integration kits sold, the number of nozzles, we aim to increase to over 1000 per printhead, and software licenses for our control software. Since our production process is highly scalable, we could produce here in Zurich until we reach that sales number. Ultimately, the decisions about manufacturing locations and company scaling will be taken together with the investors who finance it.

Speaking of locations, Scrona recently opened a regional technology center in Taiwan. Why?

It is the first internationalization step, our base to serve our semiconductor client base in the Asia-Pacific region. We have a demonstration tool and application engineer in Taiwan; our clients can come by and see it in action or come with a wafer and start printing. Working closely with clients in iterations with speed and agility convinces them that you are a reliable partner.

Written by

WITH US, YOU CANCO-INVEST IN DEEP TECH STARTUPS

Verve's investor network

With annual investments of EUR 60-70 mio, we belong to the top 10% most active startup investors in Europe. We therefore get you into competitive financing rounds alongside other world-class venture capital funds.

We empower you to build your individual portfolio.

More News

05.07.2024

“European VCs must make hard decisions faster“

In this interview, Jon Roberts, co-founder of Menalto Advisors, explains how founders can increase their odds of success and why European venture capital firms should stop financing zombie companies.

04.01.2024

Bcomp races ahead to produce bio-based car parts

In our interview, Christian Fischer, CEO and Co-founder of Bcomp, recounts the story of the startup from its humble beginnings in a garage to a supplier of global car manufacturers.

10.02.2022

“Our technology has a fundamental advantage over inkjet printing”

ETH spin-off Scrona just announced a Series A financing round of USD 9.6 million. With a printhead that has 100x higher resolution than the competition, the startup will reinvent micromanufacturing in a wide range of industries. In this interview, CEO Patrick Galliker explains how.

Startups,Innovation andVenture Capital

Sign up to receive our weekly newsletter and learn about investing in technologies that are changing the world.